The term glue filling machine, I think everyone is familiar with it. At present, the glue filling machines sold by many companies are standard, such as semi-automatic glue filling machine, automatic glue filling machine, AB glue filling machine, there is no special requirement. If there are special requirements that belong to non-standard production, then how to do non-standard glue filling machine? The following small series to introduce:

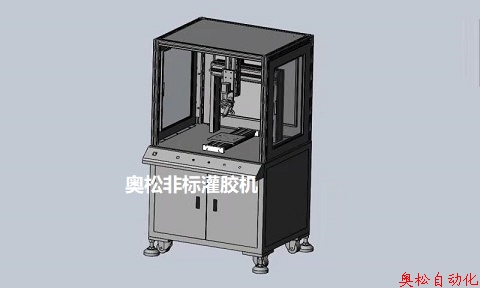

First: First, the company must have a structural engineer with design experience to design the structure of the non-standard automated AB filling machine, and draw a 3D schematic to confirm to the customer.

Second, design the details of the structure of the glue machine, the hole position and size must be carefully measured, and then the design drawings for processing.

Third: redesign the circuit diagram or compile the PLC software program. This work needs to be done by the software engineer.

The final step is the commissioning of the non-standard glue filling machine. The debugging part includes testing the structural function of the glue filling machine, confirming the proportion of AB glue glue, and a series of aging tests.

The production cycle of a non-standard automatic AB glue filling machine can be long or short, and the production cycle with relatively simple requirements is relatively short, generally 3 weeks. The complicated one is automatic filling machine or automatic dispensing machine. I hope that customers will take this into account. If they think that the time is too long, they need to determine the order in advance, and only have enough time to make a good machine with perfect functions.

Our company is a professional manufacturer of non-standard automatic dispensing machines and glue filling machines. For the requirements, please contact: 13620949195 0755-29945992 Shen Manager Shenzhen Aosong Automation Equipment Co., Ltd.