Visual Dispenser Software Patent No.: CCD Visual Recognition Dispensing Control System V1.0 Soft Ding No. 2383668

Online Visual Dispenser Overview:

Online Visual Dispenser Overview:

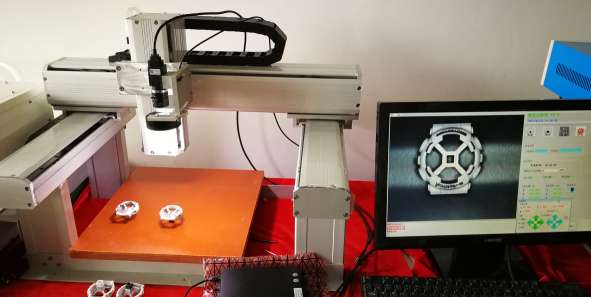

AS-431-CCD Dispenser is a three-axis automatic visual dispensing machine. It adopts the online three-axis manipulator design. The working platform is not moving, and the material feeding and feeding are carried out at the same time. Based on modern optical camera and automation, Using digital image processing, computer communication technology and mechanical integration technology, comprehensive high-tech core products, comprehensively improve your production capacity. This model uses computer control, fully automatic visual dispensing control software, and CCD vision optical system to achieve graphics Programming, easy to learn and understand, easy to operate, a variety of complex dispensing path programming, through this model, can be completed quickly and accurately.

In the process of dispensing glue, the online visual dispenser does not need to be placed neatly, no fixtures are needed, and the product only needs to be placed in the tray or working platform. The machine will according to the data provided by the imaging system. It can automatically identify the position and orientation of the product, automatically control the position of the glue and the thickness of the glue.

Online visual dispenser Features:

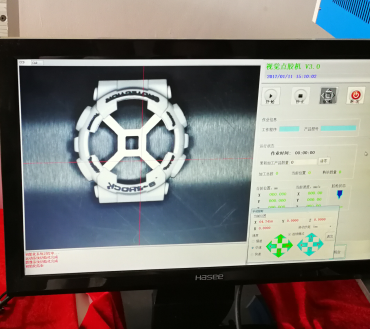

1.WINDOWS 7 Chinese operation interface, easy to learn and understand;

2. It has the functions of drawing points, lines, faces, arcs, circles, irregular tween and triaxial linkage;

3.120G hard disk has large storage memory capacity, and the software has an area array, translation rotation operation and other functions;

4. The size of the glue, the speed of the glue, the time of dispensing, the time of stopping the glue can all be parameterized, the amount of glue is stable, and the glue is not leaked;

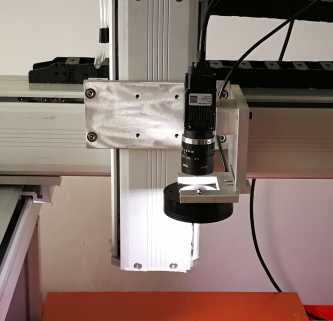

5. CCD auxiliary program editing and teaching function enables the position of the coordinate track to be tracked and displayed in real time, shortening the editing time of the program and greatly improving the programming efficiency;

6. The work platform does not move, the identification is more precise, the productivity efficiency is improved, and the production competitive advantage of the enterprise;

7. According to the process requirements, the worktable positioning PIN, glue gun or bottom plate heating temperature control device can be installed;

8. Optional multi-head fine-tuning the rubber cylinder clamp, multi-head operation at the same time, multiplying the work efficiency;

9. Optional 300CC large rubber cylinder or pressure tank storage operation, saving time for changing glue;

10. Intelligent glue breaking function prevents the glue from being pulled, which saves glue and reduces the glue repair process;

11. The glue dispensing time control resolution is 1ms;

12. It can be used for single-disc multi-clamping work, and the first-in-class can improve work efficiency.

Product Image: